Technology Innovation

Basic Philosophy

The KONOIKE Group’s business competitiveness depends on providing more attractive services, and we recognize the importance of innovation in the field to achieve greater heights in response to the recent and various changes in the logistics and warehousing industry. To this end, we opened the Konoike Institute of Technology Innovation Center (Giken IC) in March 2021, which has been at the forefront of accelerating technological innovation. It achieves this through three functions: (1) conducting experiments and proof-of-concept tests to confirm the effectiveness of new technologies and post-introduction operations by recreating various KONOIKE Group work sites at the Giken IC; (2) accelerating open innovation in which customers and vendors of new technologies gather at the Giken IC to discuss and observe the recreated sites and new technologies, and; (3) engaging in technological development with customers that meets with their future vision as part of our sales activities. In addition, we have enhanced literacy training at the group-wide level to ensure that technological innovations are instilled across the entire Group. In this way, efforts toward improvement we have taken together with field teams have gradually borne fruit. Going forward, we will continue to promote technological innovations directly related to the strengthening of field capabilities.

Medium-Term Management Plan KPI

FY3/2023

Results

FY3/2024

Results

FY3/2025

Target

Number of automation and labor-saving devices installed in the field

19

26

25

Number of POCs conducted for introducing new technology to the field

55

45

35

Number of devices introduced and technology tests at the Giken IC

13

9

12

| FY3/2023 Results |

FY3/2024

Results

|

FY3/2025

Target

|

|

| Number of automation and labor-saving devices installed in the field | 19 | 26 | 25 |

| Number of POCs conducted for introducing new technology to the field | 55 | 45 | 35 |

| Number of devices introduced and technology tests at the Giken IC | 13 | 9 | 12 |

Technological Innovation Initiatives

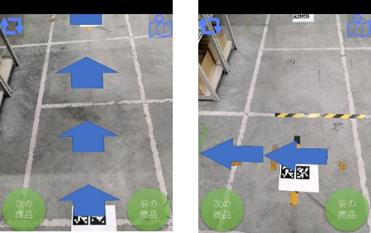

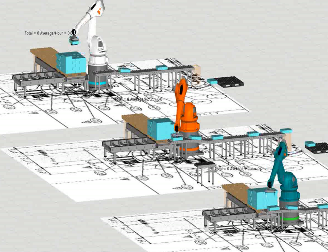

We work to improve our front lines based on the following three perspectives: ① validation testing for new technologies that enable people and technology support each other, ② maintaining and improving safety through jig and fixture developments based on work experience, and ③ improving engineering capabilities to respond to rapid changes in the business environment. We strive for our initiatives to evolve our on-site solutions by combining the latest technology with the skills of craftsmen cultivated in the field, while assessing profitability through trial calculations. In this way, we aim to create new value for our customers. From the perspective of ①, we aim to introduce technologies to create workplaces that allow people to work more easily. To do so, we aim to verify and begin operating support systems that enable workers to work in warehouse picking without hesitation and verify collaborative methods that enable guideless AGVs operation. From the perspective of ②, we internally develop specialized jigs, fixtures, and equipment based on our accumulated knowledge, introducing these tools to our work sites to create safe environments for everyone. From the perspective of ③, we aim to maximize improvements by using simulations to verify the feasibility of on-site improvement plans and grasp their effects in advance.