Package Design Service ― Optimal Designs for Packaging Materials ―

Now you can design packaging for transporting goods! This provides further added value.

Overview of Package Design for Packaging Materials

We design and manufacture transport containers based on the products and diagrams we receive. At Konoike Transport, package design refers to our service for planning, designing, producing, and delivering optimal packaging products that consider durability, affordability, and efficiency (the ease of inserting and removing products transported between plants), as well as the protective packaging for protecting products from damage during transport.

-

POINT1

"We coordinate with Kanepackage Co., Ltd., a specialist in package design.

-

POINT2

Preventing deformation and load shifting during transport can help reduce the rate of product defects caused during transport. Simplifying the structure of packaging also reduces the workload for on-site staff.

-

POINT3

Optimizing packaging reduces the risk of product damage and contributes to reduced logistics costs for the collection of returnable boxes.

-

Developing and Proposing Containers for (Molded Resin) Automobile Parts

【Issue】

Molded resin parts are used in the exterior of automobiles, so it is important that they can be both safely and efficiently transported without damage.

【Solution】

We proposed a design where the products are protected with brushed non-woven fabric so they will not collide with each other during transport, and also do not touch the packaging.

【Effect】

This proposal increased the loading efficiency, reduced costs, and reduced damage to the products.

-

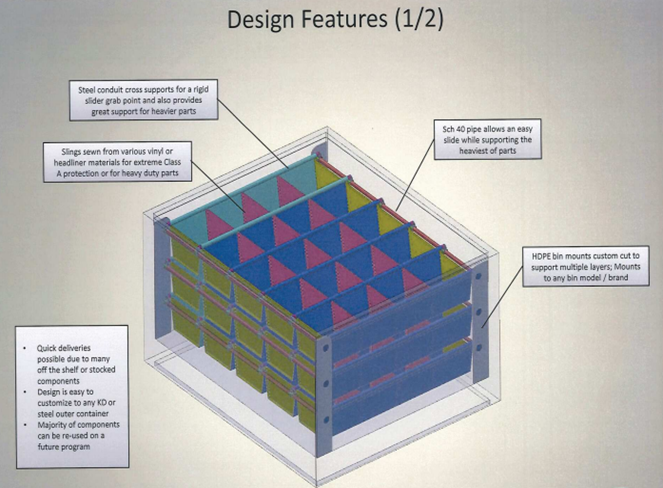

Improving Returnable Containers for Automobile Parts

【Issue】

With the returnable containers previously used for delivering automobile parts to automobile manufacturers, it was necessary for workers to move the deep, wide container from the work position in order to reach the products in the back.

【Solution】

We proposed the use of a movable non-woven rack to enable the products to be taken out from front to back without workers moving the container from the work position.

【Effect】

This proposal eliminated the need for workers to move the container from the work position at the automobile manufacturing plants, which achieved improved work efficiency, prevented back pain, and increased work safety.

About our service